MEDICAL AND PHARMACEUTICAL COMPANIES MOVE TOWARD LEANER INVENTORY AND LOGISTICS MODELS: WHY MODULA VERTICAL STORAGE SOLUTIONS ARE IN HIGH DEMAND IN THESE DYNAMIC SECTORS

Cost pressures, increasing legislations and the need for a secure and safe inventory is moving companies in the medical and pharmaceutical industry to adopt lean inventory and logistics models. Medical devices and pharmaceutical manufacturers are looking at every aspect of cost optimization from logistics & supply chain to manufacturing costs. To achieve this, they seek technologies that can help them save valuable floor space, increase productivity and accuracy and ensure a controlled secured inventory environment.

Designed to meet all these needs, Modula’s Vertical Storage are already implemented in many medical and pharmaceutical facilities across the United States.

Thanks to the enclosed system of vertically arranged trays, Modula’s Vertical Lift Modules (VLMs) utilize the available room height from floor to ceiling. This maximizes any areas storage potential. Items can be stored up to 14m high in a safe and secure unit that automatically delivers them to the operator with a simple touch on the user-friendly copilot controller or the scan of the barcode. This feature eliminates the need to search for items and ensures that the right part is delivered to the right person, to the optimum ergonomic retrieval height.

As government regulations in the industry are calling for increased focus on quality assurance, Modula units are designed to keep products of any size and shape in a secure and clean environment. The machine itself is fully enclosed with an automatic door which prevents goods from being damaged and minimized exposure to the environment.

Trays can be organized for items of every type and size. By using partitions and dividers, medical and pharmaceutical manufacturers can create the exact number of storage locations required in each tray and configuration settings can be adjusted at any time to accommodate changes in the size or quantity of the stored items. Moreover, Modula`s VLMs can be easily integrated into any existing local IT system thanks to Modula WMS, a full suite of inventory management software that provides an accurate and continuous exchange of information with minimal impact on the pre-existing procedures. This greatly reduces the risk of human errors.

By using the available data to its full potential, Modula`s software solutions offer improved inventory control and accountability. The user can monitor stock levels in real time, speed up order execution times for both picking and replenishment operations and avoid the accidental release of obsolete, expired or on-hold products.

Medical and pharmaceutical companies can have the visibility required to make good inventory decisions and reduce costs.

Modula`s traceability and validation features, such as controlled restricted access and bar code verification are also key aspects for an industry where precision, safety and accuracy are the most important bottlenecks.

Every unit is password protected, allowing only authorized operators with a personal badge and/or access code entry, to operate the machine. All picking operations are monitored and log-ins are tracked, even down to specific trays depending on the chosen level of security. Tracking access to specific trays is also beneficial for inventory control, preventing operators from picking the same items or for high valuable products to be stolen.

By adopting these storage and retrieval solutions, Medical devices and pharmaceutical manufacturers can operate in the efficient manner required and reduce the high operating costs thanks to a more flexible and efficient management of their inventory.

Benefits at a glance:

● Decreased storage footprint: Saves up to 90% of valuable floor space compared to traditional storage methods

● Full traceability and real-time inventory:All picking operations are monitored and documented to offer full traceability of the orders and monitor stock levels in real time

● Security and inventory control:With controlled restricted access and barcode verification

● Increased productivity and accuracy:With simple visual picking aids, operators can quickly and easily identify the items needed to be picked or replenished

● Secured and clean environment for products:Modula units are fully enclosed with an automatic door which prevents goods from being damaged or exposed to dust

● Easy software integration:Modula WMS can be easily integrated with any ERP or Host System

● Stock density optimization:Thanks to a height detection system, the height of each tray is measured as the tray is put away, allowing for the densest storage location to be determined in real time, maximizing the storage density within the unit. Trays can be organized for every type/size of stored item

● Ergonomic storage and retrieval workstation:Items are automatically delivered to the optimum ergonomic retrieval height

● Flexible integration & Scalable design:The units can be integrated into any existing logistics system and facility

● Quick return on investment:Anywhere from 6 to 18 months depending on the overall size of the project

● Creates new revenue activities:By reclaiming otherwise wasted space and labor

Watch our video case study at Innomed (USA):

Modula streamlines operations and efficiency at Innomed (Savannah, GA), a leader manufacturer of surgical instruments for orthopedic surgery. Thanks to 2 Modula LIFT ML50D VLM units, they now store over 90% of their inventory within the Modula VLM solutions, greatly recovering previously used floor space, while increasing user productivity and ergonomics. Items are now safely delivered to the operators at the optimal ergonomic work height, called the “Golden Zone”, avoiding unnecessary bending, walking and reaching for parts. In total, the two (2) Modula VLM units provide 1,659 ft.3 & 3,555 ft.2 of storage, all within a unit footprint of only 308 ft.2, allowing for approximately 2,400 unique instruments to be stored within each VLM unit.

Innomed | USA

Watch our video case study at Santé Service (France):

Santé Service – a French healthcare facility with over 1,300 patients, has chosen Modula to increase productivity and accuracy in their picking and storage operations. With more than 800 packages a day and 1,000 requests per hours to be shipped, without mistakes, in a very short time, Modula Lifts were the perfect solution. The 2 ML25 Lift store up to 90% of their medical stock and items are delivered automatically to the operator in a safe, accurate and fast way

Santé Service | France

Watch our video case study at Orfit Industries (Belgium):

Orfit Industries is a world leader in the development and production of thermoplastic semi-finished medical devices. With the introduction of 4 Modula ML50D Lifts, Orfit was able to dramatically increase accuracy and speed in their picking operations, going from 40 order lines/hour to over 220 order lines/hour

Orfit | Belgium

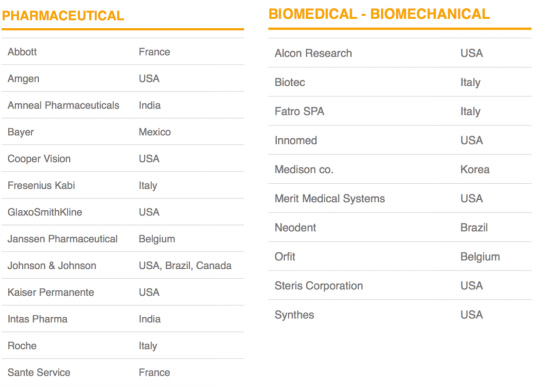

Our references in the medical and pharmaceutical industry: